How are Handmade Glass Beads Made?

Lamp-work handmade beads are made in small cottage workshops. The beads are created by heating a glass rod (known as a cane) over a flame which is today supplied by natural gas to generate the heat required to melt the glass. The molten glass is wound into the shape of the base bead pressed in a mould and turned into the desired shape. Their holes are made by copper wire, which are dissolved in nitric acid once the bead is made. Intricate surface decorations and colours can be added to the bead with limitless design possibilities. Early lamp-work beads were created with the flame of an oil lamp, hence their name.

Types of Handmade Glass Bead Decoration

The beads are decorated by “painting” trails of molten glass from smaller canes to create unique pieces of art. The process in which they are made is the same today as it was a thousand years ago. Molten glass is used to decorate the bead by “painting” with trials of molten glass from smaller canes of colour including:

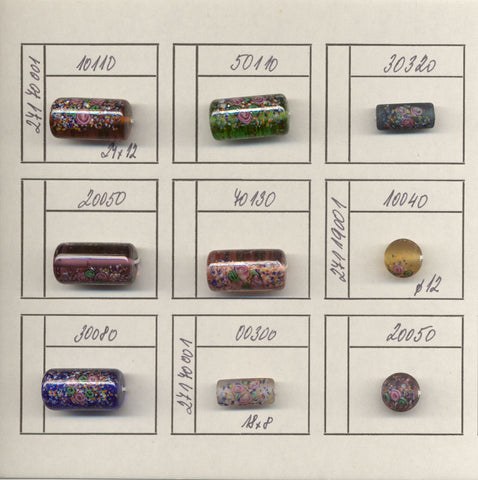

- Gold stone (aventurina) is a glass paste composed of copper powder known as gold stone, gives a shimmering or inner sparkle appearance to the bead. (crystallised from the colouring agent used in the glass.) The crystalising process occurs during a lengthy cooling of the molten glass in a special glass vessel. The process was accidently discovered on Murano about 1610-1625. Early documents also refer to aventuirna as pasts stellaria. It is avail in gold, blue or green tint. The latter two are not so common.

- Silver or gold foil is inserted beneath the top layer of glass.

- Roses are also known as paperweight beads, have a rosebud against satin glass on each side encased within a clear crystal dome.

- Swirls on the surface or core of the bead

- Sommerso is colour within layers of beads.

- Millefiori - (glass of a thousand flowers) Slices of multicoloured canes (each glass thread is barely a millimetre in diametre) incorporated into clear glass. These canes of glass are then cut into wafers, each piece bearing the original pattern in miniature; a technique that dates back thousands of years. Despite being a labour-intensive process the canes are still produced by hand and produce distinctive decorative patterns.

- Dichroic glass is a multi-layer coating placed on glass by using a highly technical vacuum coating deposition process. Quartz crystal and metal oxides are vapourised with an electron beam gun in an airless vacuum chamber and the vapour then floats upward and attaches then condenses on the surface of the glass in the form of a crystal structure. Some colours have as many as 30 layers of these materials, yet the thickness of the total coating is approximately 35millioniths of an inch. The coating that is created is very similar to a gemstone and by careful control in thickness, different colours are obtained. The coatings are created using the same materials originally created by the Aerospace industry. This process creates two colour shifts depending on the angle and view of light. The result is truly unique! I.e., it has a transmitted colour and completely different reflective colour.

- Chevrons were first produced by the venetians from 1500s. They are a draw glass cane bead design with usually 7 moulded layers and 12 points. They are formed by blowing a single or multiple layered gathers of glass into a tapered mould with corrugated sides, thus producing points on its outer surface. This pleated gathering is subsequently encased with additional glass layers if carious colours, which again be moulded to produce further outer layers with points. Finally, strips may be applied to the outer surface. Still viscid, this multi layered hollow gather is then quickly drawn into a cane of at least 2m, cooled and finally sectioned into beads. In the1800s. The Venetians produced chevrons in great numbers with 4 or 6 layers in red, white, and blue which were traded in West Africa. We stock some reproduction chevrons made in India in the 1980s.

Their beauty, therefore, makes them a great choice for the focal point in your jewellery, or simply as an additional accent.

Venetian Glass Beads

Moretti, on the island of Murano, was established in 1911 by three brothers. The initial production was limited to two types of beads, the chevron and the African mosaic.

With the success of these styles, they widened the range to millefiori (thousand flowers) Sommerso (colours within layers of glass) and painted roses, the style of the green beads.

In 1968 they developed murrine pendants, which in a few years became the souvenir of choice for many tourists.

This happens because of the alloy mix in brass. The copper color you see is a result of the piece being fired. The heat depletes zinc on the surface layer, which means there is a higher percentage of copper remaining.

The Roman glass industry evolved into a bead centre on the island of Murano, which dominated the world bead trade from the Renaissance.

In 1292 glass makers were moved to the island (by mandate of the Doges of Venice) as there was a great risk of fire by the furnaces destroying homes which were made entirely of wood.

The glass workers were forbidden (punishment by death) to reveal their secrets or emigrate.

Glass bead making techniques are still passed down by word of mouth.

The glass industry was highly organised and was strictly controlled by the Guild of Glassmakers.

A vast trading fleet sustained this virtual monopoly, importing raw materials & exporting finished goods.

By the middle of the 16th century the Venetians had perfected major techniques of making and decorating glass.

Indian Glass Beads

With a love of decoration beaded jewellery plays an important part in Indian life.

India imported European beads in earlier centuries. (under the Roman Empire, with the discovery of New Continents by explorers including Marco Polo beads were traded from the 15th on wards)

India now however produces vast amounts of glass beads as well as metal, silver, wood and semiprecious.

Bead making is divided into special guilds according to the materials and techniques used.

(Similar to the Ancient Egyptian System).

The techniques and quality of the beads have improved over the years and India now produces fancy glass work by the Venetian artisans. Even though they are not as nice as the real thing – these beads make a very worthwhile substitute and cheaper.

Indian glass has an obvious roughness about it that can really add to your work when a hand-worked look is required. We love the chunky foil lined “mexican” beads that have become popular in recent years reflecting the vibrant colours and the bold shapes of Mexico.

Most beads are made in kiln (furnace) beads are made in a similar way to lamp beads, the main difference being the heat source.

Care for Glass Beads

The white powdery core is from the China clay used as release agent when the glass is wound onto the metal rod.

The process of making glass is chemical. It is therefore best to clean your beads to ensure there is no residue left on the beads. This also makes them sparkle and shine. Soap and lukewarm water work well. There is no need to use stronger solutions.